Tyrefield is the state-of-the-art sports surface made with recycled rubber from End-of-Life Tyres. It is environmentally friendly, advantageous and performing.

Recycled rubber from End-of-Life tyres is, indeed, a mix of polymers of extremely high quality. It has the ideal characteristics for the production of sports surfaces: it has an excellent elastic response, it resists even the worst weather conditions, and it is highly shock absorbing.

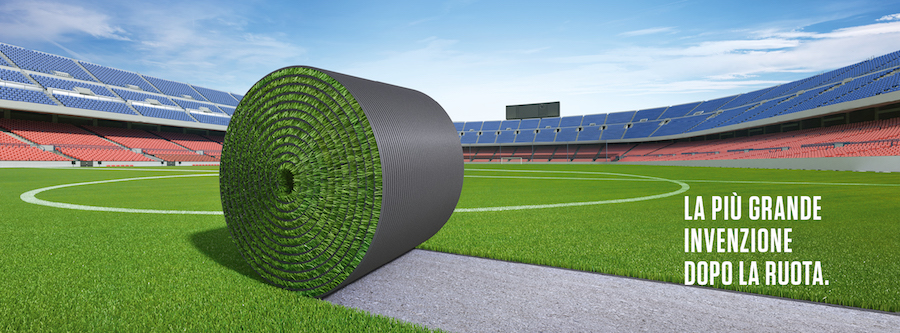

Used in the form of granules, rolls, or prefabricated bricks, recycled rubber is widely used all over the world for the realisation of artificial turf football pitches, athletics tracks, indoor and outdoor multipurpose floorings for basketball, tennis and volleyball, anti-shock floorings for gyms and playgrounds, surfaces for animal wellbeing, and much more.

Football

In Tyrefield synthetic turf sports surfaces, recycled rubber granules are used as an infill material between the blades of grass or for the sub-layer underlying the playing surface. In the second case, they form a special mat equipped with drains, they favour the levelling of the foundations, make the surface more elastic, and favour the absorption of shock and the return of energy to the athlete, at the same time draining rain.

In Tyrefield synthetic turf sports surfaces, recycled rubber granules are used as an infill material between the blades of grass or for the sub-layer underlying the playing surface. In the second case, they form a special mat equipped with drains, they favour the levelling of the foundations, make the surface more elastic, and favour the absorption of shock and the return of energy to the athlete, at the same time draining rain.

The infill with ELT rubber granules, instead, is used for shock-absorption and it prevent the vertical deformation of the surface, and maintain high qualitative standards for the rolling and bouncing of the ball. At the same time the infill keeps grass blades straight and helps it to go back to its original position after it has been stepped on.

See all the informations about artificial turf pitches with recycled rubber!

The advantages of the use of recycled rubber are more and more appreciated also by sports clubs at the highest national levels. Already in 2014 Atalanta FC, in partnership with Ecopneus, created a state-of-the-art football pitch in recycled rubber for its own sports centre of Zingonia-Cesarano (Bergamo). This pitch is used for training and the matches of their youth division. In June 2017, also Bologna FC1909 chose an artificial turf football pitch with recycled rubber and organic material infill for its own sports centre in Casteldebole, Bologna. This pitch is used also for athletes’ rehabilitation thanks to the specific characteristics of its turf.

A Project research carried out by Prof. Mauro Testa’s team – leading expert in biomechanics at international level – in collaboration with the company Captiks to analyse footballers’ sports activities on two different sports surfaces: the new Bologna FC1909 Tyrefield pitch with recycled rubber and a natural turf pitch. The many data collected thanks to a highly technological methodology have allowed to demonstrate that synthetic turf sports surfaces with rubber infill have the same performances of a professional natural turf pitch. This further improves performances and economic advantages. Indeed, synthetic turf surfaces undergo fairly modest ordinary maintenance. This was also stated by Roberto Spagnolo, Atalanta BC’s Operative Director: “today we can state with certainty that, as an average, the cost reduction obtained with a Tyrefield synthetic turf pitch is over 50% compared with a natural turf pitch”.

Watch the engaging video on the new Bologna FC1909 Tyrefield with players and staff members:

Multi-purpose, indoor and outdoor surfaces

Multi-purpose Tyrefield sports surfaces with recycled rubber can be made “in situ coating” a mix of rubber granules with polyurethane resins, or assembling some recycled rubber prefabricated tiles to create a single surface. In both cases, a coloured acrylic resin is subsequently applied above the rubber layer, which guarantees the correct grip and on which the lines to define the playgrounds are painted. These are the typology of flooring present, for example, in school premises, in sports centres or in gyms and are appropriate for the almost totality of disciplines: from volleyball to basketball, from gymnastics to dance, from handball to 5-a-side football.

Multi-purpose Tyrefield sports surfaces with recycled rubber can be made “in situ coating” a mix of rubber granules with polyurethane resins, or assembling some recycled rubber prefabricated tiles to create a single surface. In both cases, a coloured acrylic resin is subsequently applied above the rubber layer, which guarantees the correct grip and on which the lines to define the playgrounds are painted. These are the typology of flooring present, for example, in school premises, in sports centres or in gyms and are appropriate for the almost totality of disciplines: from volleyball to basketball, from gymnastics to dance, from handball to 5-a-side football.

Find out more information about multi purpose Tyrefield sport surface!

By appropriately modulating the characteristics of the external wear layer of the flooring, with the thickness and the peculiar physical properties of the underlayer in recycled rubber, it is, indeed, possible to affect the response of the sport surfaces, thus, satisfying the vast majority of athletes’ and managers’ requests, as well as the ones of the most demanding coaches.

Even at the Sports Festival of Trento two Tyrefield sports surfaces were made: one for volleyball and the other for basketball.

Playgrounds

Do you have in mind those colourful tiles that can be found in many playgrounds and public areas under play facilities such as swings and slides? Perhaps you may not know it, but the vast majority of them is made with the rubber recycled from End-of-Life Tyres.

Do you have in mind those colourful tiles that can be found in many playgrounds and public areas under play facilities such as swings and slides? Perhaps you may not know it, but the vast majority of them is made with the rubber recycled from End-of-Life Tyres.

Recycled rubber is, indeed, an excellent material for the creation of children’s playgrounds and anti-shock floorings thanks to its resistance to sudden hits without breaking, which also guarantees its long duration in time. They can be made either by putting together prefabricated mats and by laying a mixture of coloured rubber granules and polyurethane resins, melted in place to create a single surface. It is a choice based on good civic sense but also a legal obligation: The European regulations require the positioning of anti-shock floorings under every playground structures higher than 60 cm in terms of free fall. This European rule (EN 1177) has been developed by the technical committee CEN/TC 136 “Sports, playgrounds and other free time structures”. Within its scope, Ecopneus takes part to the works of the group “sports floorings”.

An example of this kind of successfully application of recycled rubber is visible also in Festambiente, the national festival of Legambiente, which is held every year in Rispescia (Tuscany).

Surfaces for horse riding and animals’ wellbeing

Inside horse riding centres and stables, an adequate rubber flooring guarantees a soft and comfortable support to the horse. It insulates from damp, hot or cold floors; it compensates for floor unevenness; it noticeably improves the hygiene in the stable and it annuls the risk of slipping. Moreover, the use of this solution allows to considerably reduce, and in certain cases to completely eliminate, the costs for bedding materials, such as hay or chips.

Inside horse riding centres and stables, an adequate rubber flooring guarantees a soft and comfortable support to the horse. It insulates from damp, hot or cold floors; it compensates for floor unevenness; it noticeably improves the hygiene in the stable and it annuls the risk of slipping. Moreover, the use of this solution allows to considerably reduce, and in certain cases to completely eliminate, the costs for bedding materials, such as hay or chips.

However, horses and riders spend the largest part of the day working in outdoors fields which are usually made of sand. This material can release fine particulates during the practice of the sport and may cause the insurgence of respiratory pathologies linked to silicosis. This respiratory pathology is very common among horses, but it can affect also the riders who spend many hours on these surfaces. The horse’s hooves as well as the constant consumption of sand granules release in the air some micro particles of silica, that end up in the pulmonary alveoli, thus causing damage that can be also serious.

Even in this case it is recycled rubber that comes to rescue: by replacing sand with recycled rubber granules, either wholly or in mixes of sand and rubber, the dispersion of particles in the air is reduced in such a consistent way that, in certain cases, it is not even necessary to wet the external area before starting the activities with the horses.

For example, a field with this innovative technology has been made in Orvieto, where we have also made a funny video clip with the mare Juanita. Her problem? She was allergic to hay!

All its advantages:

- Reduction of animals’ long-term damage to their legs

- Anti-slip and resistant to animals’ hooves

- Increase animal’s comfort and health, amortizing its movements and eliminating the risk of slippery grounds

- Application on any type of surface, even uneven ones, such as grass, soil or sand

- Easy to install and adapt to any form and extension

- Duration, resistance to wear and bad weather, reduction of maintenance or replacement costs

- Hygienic, easy to clean and insulating from dirty grounds and liquids

Moreover, in collaboration with the Department of Veterinary Medicine of the University of Perugia, and within the scope of its partnership with UISP-Italian Union Sports for Everybody – Ecopneus has started a research project to test the reduction of accidents to horses’ limbs and the lower incidence of respiratory pathologies thanks to the use of surfaces made with rubber recycled from End-of-Life Tyres.

If you would like to find out more about the advantages and characteristics of horse riding surfaces made with rubber recycled from ELTs, download our brochure: “Recycled rubber floorings: the future of horse riding centres and stables has a new ground“ (in italian).

Collect ELT

Collect ELT