The advantages of asphalts modified with recycled rubber

The rubber a tyre is made of is a mixture of high quality polymers. Added to bitumen or bituminous conglomerates, it modifies their physical properties, thus noticeably improving the overall performance of the road surface. Indeed, it allows:

- a 3/5 dB average reduction of the noise generated by the tyre in contact with the road;

- Long-lasting and exceptional resistance to wear. International trials have demonstrated that a rubberised surface can last up to three times longer than traditional asphalt;

- Greater resistance to the formation of cracks of all types and to weather action. This guarantees the duration of asphalt characteristics in time and a reduction in maintenance interventions. As a consequence, it also reduces the inconvenience caused by road works and their related costs.

- Greater Safety, thanks to excellent grip, water drainage and improved visibility. Its greater resistance to the formation of potholes increases citizens’ comfort and reduces accidents.

- Recovery of quality second raw material, reducing the use of specific production additives (mainly coming from abroad). These are also more expensive and have higher financial and environmental costs. As such, saving on these additives advantages also the Italian economy.

The combination of all these benefits implies an important reduction of maintenance costs, CO2 emissions, and the use of virgin raw materials.

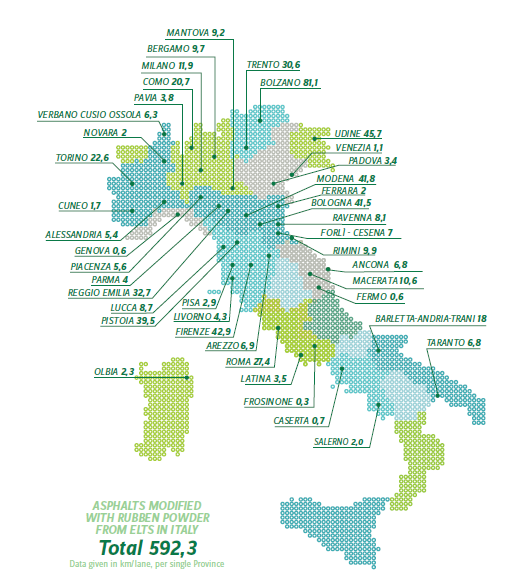

Rubberised asphalt use in Italy

In Italy, the use of this technology has consolidated in time thanks to the constant effort of Ecopneus. Ecopneus is a non-profit company and is the main operator in the management of End-of-Life Tyres in Italy. It assures the tracing, collection, and recovery of an average of 200,000 tonnes of ELTs every year.

In Italy, the use of this technology has consolidated in time thanks to the constant effort of Ecopneus. Ecopneus is a non-profit company and is the main operator in the management of End-of-Life Tyres in Italy. It assures the tracing, collection, and recovery of an average of 200,000 tonnes of ELTs every year.

The interest for this application has been constantly growing since 2006. Indeed, about 600 km of roads have been made with this technology in Italy as of today.

Within the scope of urban and sub-urban viability (council), rubberised asphalts aim at reducing traffic noise. For what concerns extra-urban viability, instead (provincial, regional, and national viability), the main objective is to increase the durability and the maintenance of the structural characteristics in time, as this traffic is characterised by heavy-load vehicles and faster travelling speed. In any case, even for extra-urban viability, the benefits linked to noise reduction are worth of notice.

Applications of such technology with good feedback have been made even on motorways, in particular on the A/22 AutoBrennero, Autostrade per l’Italia, A/24 Autostrada dei Parchi and A/33 Autostrada Asti Cuneo.

Currently, all the surfaces made with this technology require minimum maintenance interventions even after more than a decade since their creation.

Longer life

The longer life of modified asphalts has been confirmed by many tests and interventions carried out on the Italian territory. Indeed, the addition of rubber powder guarantees elasticity to bitumen. This aspect allows to obtain a greater resistance to the creation of cracks and fissures of any type. Moreover, it noticeably reduces the need for maintenance interventions and their related costs, as well as the inconvenience caused by road works.

The longer life of modified asphalts has been confirmed by many tests and interventions carried out on the Italian territory. Indeed, the addition of rubber powder guarantees elasticity to bitumen. This aspect allows to obtain a greater resistance to the creation of cracks and fissures of any type. Moreover, it noticeably reduces the need for maintenance interventions and their related costs, as well as the inconvenience caused by road works.

From the many analyses and monitoring activities carried out to ascertain the state of service of the roads made with modified asphalts, it emerges that the mechanical and acoustic performances of rubberised asphalts have basically remained identical to the moment they went into service, even 10 years after their creation.

Reduced noise emissions

One of the main advantages of modified asphalts is their noiselessness. By appropriately designing the bituminous mixes, it is possible to obtain an asphalt that can achieve an up to 5dB reduction in the noise generated by the passage of vehicles. This value corresponds to the halving of the sound energy perceived by the human ear. It is not a secondary aspect, considering that 1/5 of the EU population is exposed to excessive noise levels and, according to the World’s Health Organisation, noise pollution causes over 10,000 premature deaths every year in Europe. Moreover, Italy is currently subject to an EU’s infraction procedure for not having done enough for preventing and contrasting excessive noise levels. This is a further reason for incentivising the use of this valid technology, especially in urban contexts.

One of the main advantages of modified asphalts is their noiselessness. By appropriately designing the bituminous mixes, it is possible to obtain an asphalt that can achieve an up to 5dB reduction in the noise generated by the passage of vehicles. This value corresponds to the halving of the sound energy perceived by the human ear. It is not a secondary aspect, considering that 1/5 of the EU population is exposed to excessive noise levels and, according to the World’s Health Organisation, noise pollution causes over 10,000 premature deaths every year in Europe. Moreover, Italy is currently subject to an EU’s infraction procedure for not having done enough for preventing and contrasting excessive noise levels. This is a further reason for incentivising the use of this valid technology, especially in urban contexts.

Safety

Modified asphalts allow greater driving safety, thanks to better road-holding, water draining, and improved visibility. The greater resistance to the formation of potholes and a very effective drainage guarantee excellent visibility and safety for drivers, increasing citizens’ comfort and reducing accidents, also thanks to the reduction of aquaplaning.

For further reading

The technical handbooks on modified asphalts

In collaboration with universities and research centres, Ecopneus has promoted a series of handbooks where technical aspects, case histories, formulations, and performances of the various typologies of rubberised asphalt are scientifically presented. The objective is to favour the circulation of information and technical updates among all the subjects of the Italian asphalt chain. In its turn, this greater circulation of information aims at leading to a wider use of this valid application on our roads. Download them all!

08. Prestazioni acustiche degli asfalti modificati in scenari urbani

13. Guida per la produzione di bitumi con polverino di gomma da PFU

16. La Variante Canali di Reggio Emilia: una strada green

17: Strati di usura con polverino da PFU per la viabilità urbana

Collect ELT

Collect ELT