An innovative prototype of safety barriers for motorcyclists entirely made with recycled rubber from End-of-Life Tyres: a concrete and sustainable solution to the growing need of greater safety for motorcyclists.

ANAS (Group FS) has positively tested a new environmentally-friendly safety device made with rubber recycled from End-of-Life Tyres. The project was wholly designed by an ANAS architect. It was, then, carried out in collaboration with Ecopneus and Proge Plast. This device was designed to assure greater safety for motorcyclists and it complies with the need of making the road infrastructure more sustainable and performing at the same time.

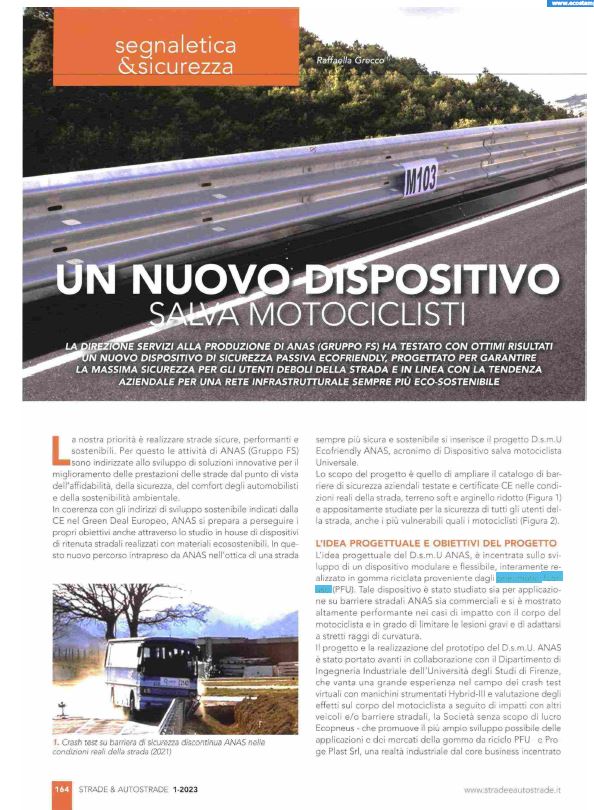

The prototype was tested with great results. It represents an innovation that combines performances and sustainability in a single device that can be installed on ANAS road barriers as well on commercial ones. It was particularly performing in those cases when the motorcyclist’s body came into contact with it. Indeed, it was able to reduce serious injuries thanks to its capacity of adapting to tight steering.

The prototype was tested with great results. It represents an innovation that combines performances and sustainability in a single device that can be installed on ANAS road barriers as well on commercial ones. It was particularly performing in those cases when the motorcyclist’s body came into contact with it. Indeed, it was able to reduce serious injuries thanks to its capacity of adapting to tight steering.

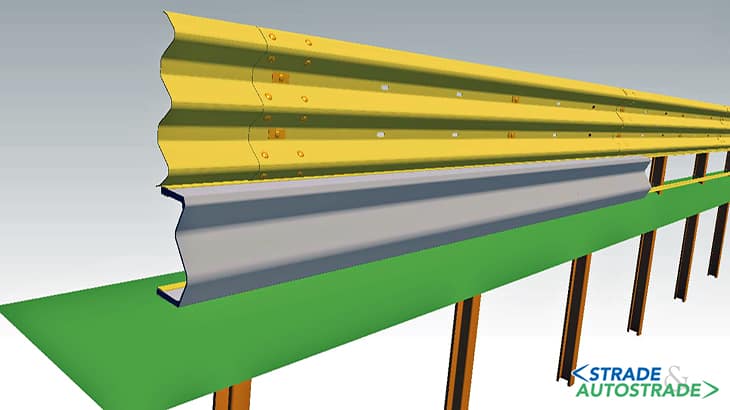

The ANAS Ecofriendly D.s.m.U Project, (D.s.m.U being an acronym for Universal Motorcyclists’ Safety Device) provides for a structure that offers maximum safety performances for motorcyclists thanks to the combination of its design and the composition of the very elastic material used to produce it: the Tyreplast compounds. Tyreplast compounds were born from the combination of ELT-derived rubber with thermoplastic materials. They combine technical performances and quality; they valorise the elasticity and shock absorption characteristics that belong to recycled rubber and, at the same time, they are sustainable.

The sustainable motorcyclists’ safety device made with recycled rubber assures safety to all road users. In particular, motorcyclists can benefit from it, as the crash tests have demonstrated. Moreover, it offers many advantages: it is a flexible and modular device and can be adapted to the different radius of road curvature. It is also easy to install thanks to a system that locks it onto the road barrier posts. Thanks to this interlocking system, it also assures road continuity. An equally important aspect of this innovative motorcyclists’ safety device is the fact that it does not require maintenance or renovation following a motorcyclist’s impact. The rubber the Tyreplast compound is made of has elastic properties; as such, it is able to go back to its initial shape, thus reducing maintenance costs to zero.

The sustainable motorcyclists’ safety device made with recycled rubber assures safety to all road users. In particular, motorcyclists can benefit from it, as the crash tests have demonstrated. Moreover, it offers many advantages: it is a flexible and modular device and can be adapted to the different radius of road curvature. It is also easy to install thanks to a system that locks it onto the road barrier posts. Thanks to this interlocking system, it also assures road continuity. An equally important aspect of this innovative motorcyclists’ safety device is the fact that it does not require maintenance or renovation following a motorcyclist’s impact. The rubber the Tyreplast compound is made of has elastic properties; as such, it is able to go back to its initial shape, thus reducing maintenance costs to zero.

Recycled rubber powder or granules are adequately mixed with several typologies of thermoplastic materials thanks to the use of specific compatibilizers. This process transfers some characteristics typical of rubber to the polymeric matrix, such as elasticity, shock resistance and vibration absorption. This process increases and modifies the functional characteristics of the Tyreplast materials. These products have been developed and designed to be treated and transformed with state-of-the-art technology without the need of specific treatments.

The project has been developed by ANAS in collaboration with the Department of Industrial Engineering of the Università degli Studi of the city of Florence. This university boasts great experience in the sector of virtual crash tests with instrumental Hybrid-III dummies and evaluations of the effects on motorcyclists’ bodies following their crashing into other vehicles and/or road barriers. The other partners of the project were Ecopneus and Proge Plast Srl. Ecopneus is dedicated to the promotion and the development of new applications and markets for rubber recycled from ELTs. Proge Plast Srl, instead, is a company whose core business focuses on the engineering and development of products made with polymers and rubber materials.

For further information, read the full article in Strade&Autostrade or online on Strade& Autostrade.it

Collect ELT

Collect ELT