Among the events planned at Ecomondo, there will be the online seminar dedicated to ELT energy recovery with the speeches of Ecopneus, The Foundation for a Sustainable Development, Geocycle, and M&IT Consulting

About 400,000 tonnes of ELTs – End-of-Life Tyres – are produced from the spare part market and the scrapping of vehicles in Italy every year. Of these, about 200,000 tonnes are collected and recycled by Ecopneus every year. Ecopneus is the non-profit company among the main players of ELT management in the spare part market in Italy.

It is a management system that has transformed ELTs in a precious resource in ten years. Moreover, it guarantees the collection and recovery of 100% of the ELTs generated by tyres regularly placed on the spare part market by its partners.

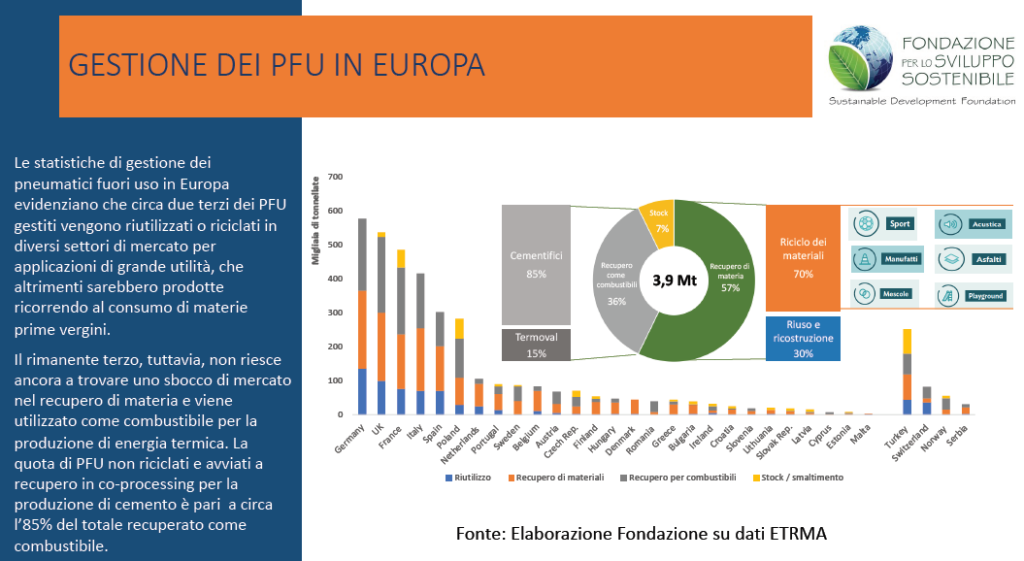

(PIC 1) The management of ELTs in Europe– Speech by Massimiliano Bienati – Foundation for a Sustainable Development

End-of-Life tyres can follow a double recovery path: the recovery of materials, or energy recovery. For what concerns the recovery of materials, with this process, it is possible to obtain recycled rubber for many applications, for example: sports, asphalts, the building sector and steel. Otherwise, ELTs can be used for energy recovery as an alternative fuel in highly energy-consuming plants, where they replace traditional fossil fuels.

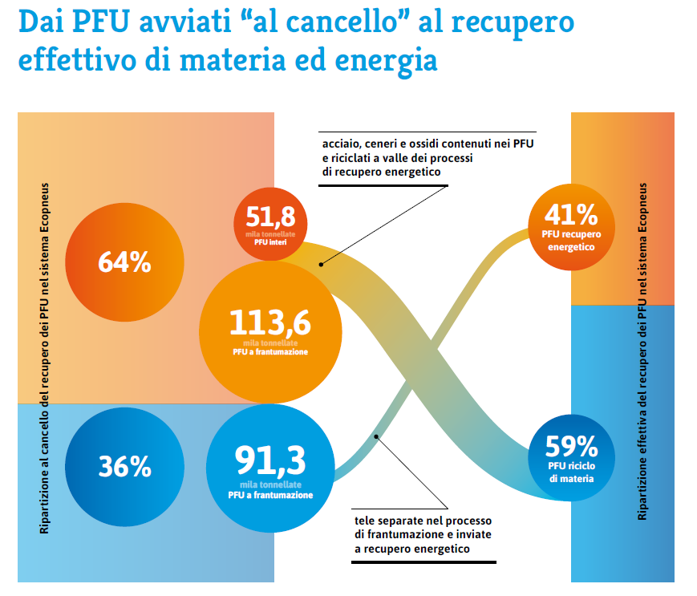

If Ecopneus is strongly committed to ELT rubber recycling, it equally focuses on the preparation of the recovery of ELTs as alternative fuels for the production of electrical power. Indeed, the energy recovery of ELTs represents a fundamental component to be able to assure the 100% of the virtuous recycling of ELTs, especially with reference to an internal market of rubber recycled from ELTs that is still not mature enough to absorb all available material.

(PIC 2) From the “to-gate” ELTs to the effective recovery or material and energy – Speech by Daniele Fornai – Ecopneus

The energy recovery of ELTs is mainly carried out in cement factories. This allows to better exploit the high calorific value of rubber, which is higher than pet-coke, as well as recover the combustion residues – ashes and steel – as materials. These are then added to the end product, avoiding the use of further virgin raw materials, with an environmental and financial benefit for companies and society. Indeed, the use of ELTs as fuel in cement factories to replace other fossil fuels allows for a reduction of CO2 emissions of the life cycle and for the saving of virgin raw materials used in the production – especially iron oxides – thanks to the steel present in ELTs. Indeed, the release into the atmosphere of 1 tonne of CO2eq is avoided for every tonne of ELTs used in replacement of pet-coke, as well as the consumption of 210kg of mineral and fossil virgin raw materials.

The option of energy recovery is, thus, an unavoidable choice to allow the environmental and financial sustainability of the whole sector. Ecopneus intends taking its own vision on the strategic role of ELT energy recovery to Ecomondo transparently and within the scope of an open dialogue with its own stakeholders. It will do so by presenting the online seminar “The energy recovery of End-of-Life Tyres: Quality, standards and best practices in a sustainable and efficient recovery path” This seminar will be held next Wednesday 4th November from 15:00 to 16:30. It will be possible to follow this seminar in streaming.

The following experts will take part this event: Daniele Fornai, in his role of person responsible for the Operations of Ecopneus and Chairman of the event, Mauro Nolli, Senior Partner and Manager of M&IT Consulting, Responsible for the Industry and Operation department, Marco Turri, Sales and Marketing Manager of Geocycle, and Massimiliano Bienati, Project manager of the “Studies and research” department of the Foundation for a sustainable development.

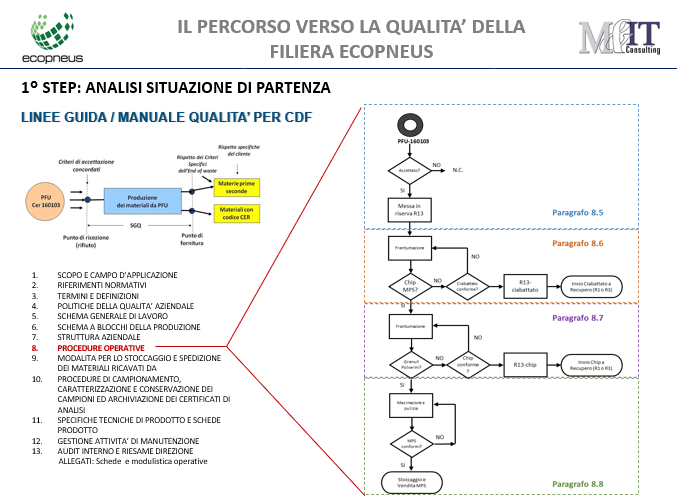

The path set by Ecopneus also on this front is based on the importance of Quality along all the stages of the chain and on the definition of unique and recognised standards. It is an activity of R&D carried on also thanks to the collaboration with highly-specialised third parties. Indeed, the strategy of Ecopneus is to identify only companies of proven reliability and high sustainability standards as the recipients of such flows of ELTs, thus assuring a meaningful environmental benefit also to such uses.

The effort of Ecopneus to set up a cycle of solid and controlled energy recovery has already given concrete results: an improvement of Quality Management in the companies of the chain, R&D work on the textile part, classification of the fuel as SSF.

For further information

Daniele Fornai’s speech – Ecopneus

Mauro Nolli’s speech – M&IT Consulting

Massimiliano Bienati’s speech – Foundation for a Sustainable Development

Watch the full recording of the conference dedicated to the Energy Recovery of End-of-Life Tyres

Collect ELT

Collect ELT